Helmet Liner Systems.

Viconic Energy Absorbing System

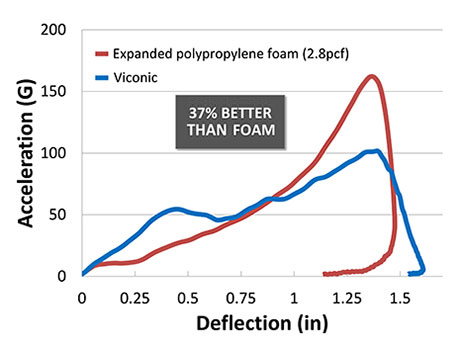

Performance

- Loads up faster than foam

- More stroke than foam

- Highly efficient force vs. deflection curves

Benefits

- Customized performance – Impact absorber shape customized for each impact location, while competitive foam pads are mono-density

- Easily tuned – Impact absorber stiffness tuned by changing sheet thickness without need to modify tooling

- Stable – Impact absorber conforms to head shape and is suspended in shell to improve stability over foam pads

- Recoverable – Protects against multiple impacts

- Long life cycle – Made from durable and washable materials

- Prototype tooling can be easily modified to adjust design parameters as needed

- Customized structures and impact protection throughout the energy absorber

- Rapid performance optimization

Cost

- Rapid/low cost prototype development

- Lower tooling cost than foam and injection molding

Storage and Transportation

- Parts nest for up to 90% space reduction

- Requires less plant floor space, lower shipping costs, lower handling costs

Comments are closed.

![]()